See beyond, Detect Smarter

- Intelligent Visual Monitoring Solution

-

A predictive AI-based monitoring system that detects anomalies in the manufacturing

environment in real time through video analysis and sensors, proactively eliminating potential risks.

- Integrated Intelligent Analysis Solution

- VARAVIEW is an integrated intelligent analysis solution that combines AI-based video analysis with temperature, vibration, and noise sensor data to diagnose and improve operational efficiency, yield, quality, and safety in industrial and manufacturing sites in real time.

- AI-Based Alerts

- Detect anomalies in advance through AI-powered equipment operation video analysis, and instantly notify users of changes with intuitive pop-up alerts.

- Precision Analysis Solution

- Through PLC integration, the system tracks the root cause of equipment issues and provides a precision analysis–based solution to improve productivity (uptime, yield, and quality).

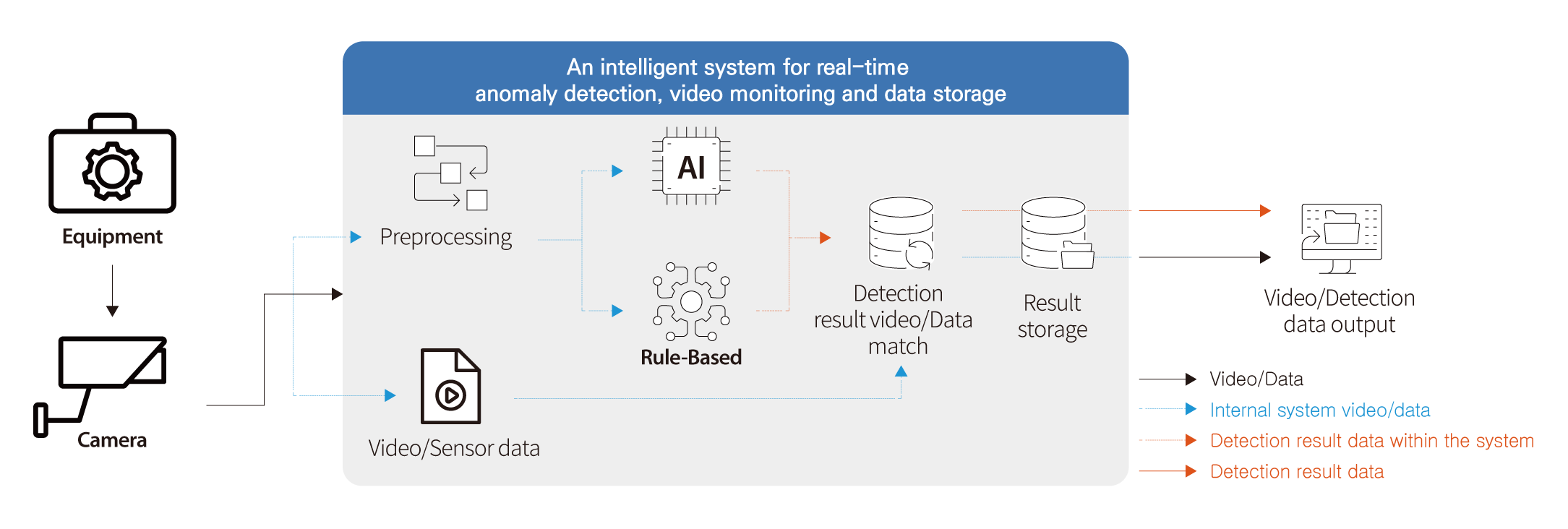

System Architecture

Product

Camera

- 2~5 MP resolution

- Precise and stable imaging enabled by Rolling/Global Shutter

- Collects vibration, noise, temperature and humidity data

- Operates wirelessly without power or communication cables

Intelligent NVR

- Supports AI-based learning and classification in

addition to the existing video storage function of NVR

- Equipped with an efficient UI enabling the user to

quickly identify errors within videos

VARAVIEW Solution

Manufacturing

① Analysis of equipment utilization, yield and quality

② PLC integration and root cause identification of equipment downtime

③ Early detection of equipment anomalies

Industry

① Heavy equipment monitoring

② Safety accident prevention

Logistics

① Logistics automation / downtime monitoring

② Inventory monitoring

Facility Management

① Public facility safety monitoring

② Access control

③ Environmental sensor integration

VARAVIEW Solution Use Cases

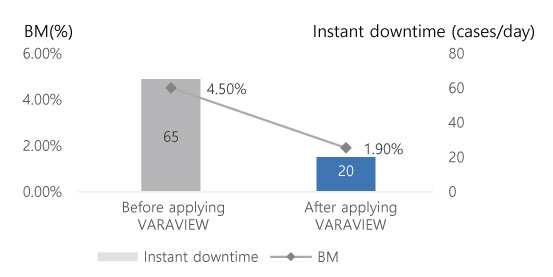

In secondary battery manufacturing, applying VARAVIEW has improved equipment BM (breakdown machines) and reduced workload for engineers.

Equipment downtime issues · Yield/Quality issues · Safety and environmental issues

On-site checks (repeated continuously)

Cause analysis (speculation)

Improvement plans

VARAVIEW Monitoring

Root cause analysis

Improvement plans (recurrence prevention)

Maximizing equipment utilization — BM reduced from 4.5% → 1.9%, 70% reduction in instant downtime

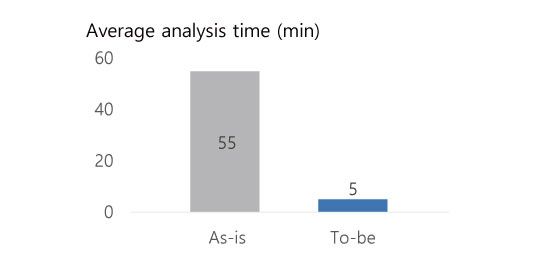

Engineer analysis load time improved by 90%

Secondary battery manufacturing — Enhancing product yield and quality by monitoring and analyzing critical processes up close

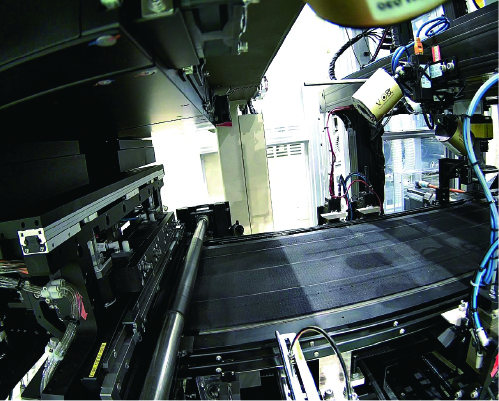

Cylindrical winding unit

Cylindrical welding (+) unit

Pouch/Angular cutter

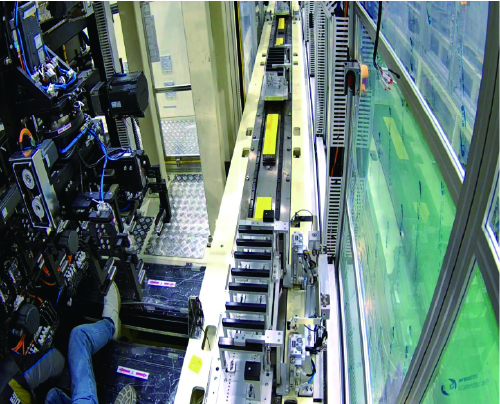

Secondary battery manufacturing — Enhancing equipment utilization and safety in environment by monitoring and analyzing equipment operation

Cylindrical cell transfer unit

Pouch/Angular cell transfer unit

Tray logistics