Detection Solution

We provide a system that can proactively detect product and safety issues and issue warnings.

- Monitoring

- Intelligent System

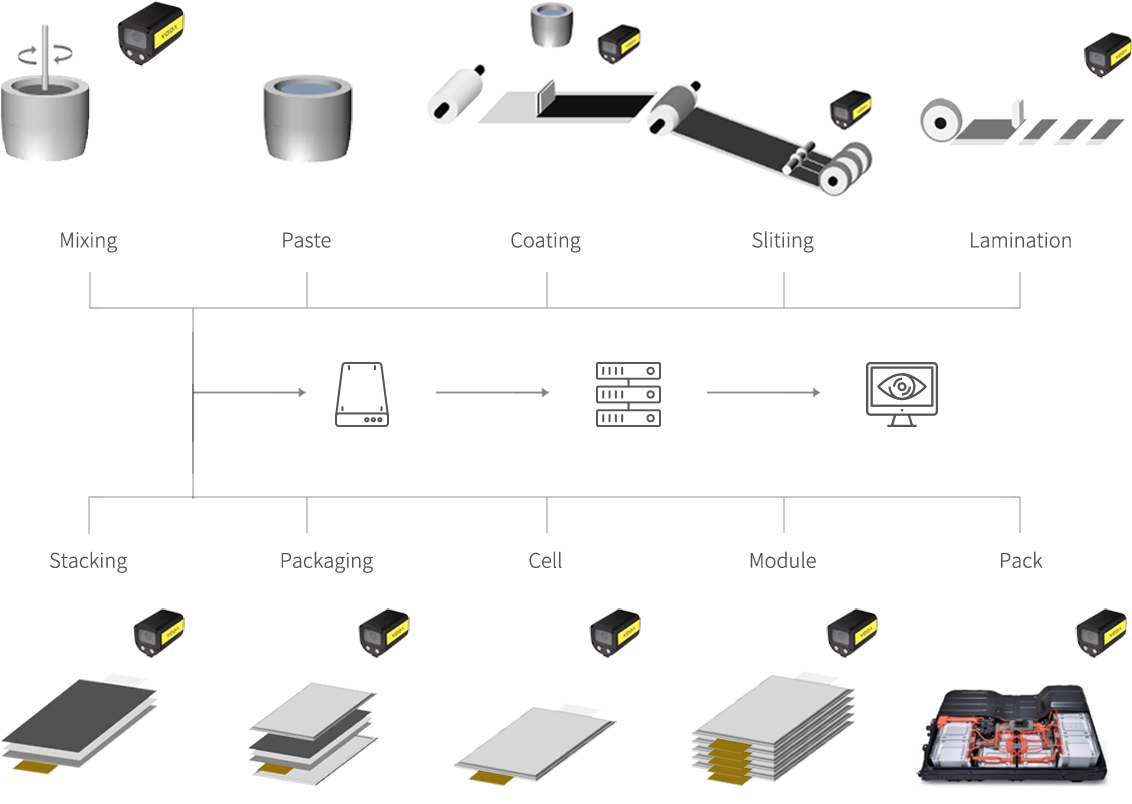

Secondary Battery Monitoring

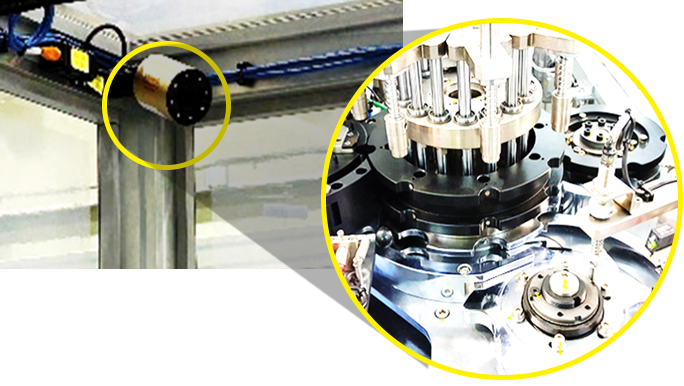

Monitoring Equipment Configuration

Logistics Monitoring

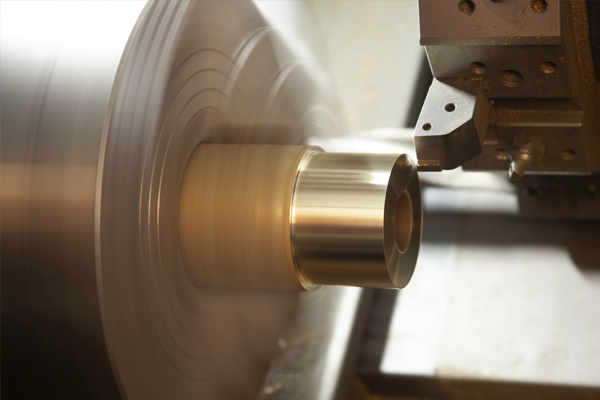

Rotating Equipment Monitoring

Process Monitoring

Intelligent Monitoring

- Abnormal Equipment Operation Detection

-

- Detection of abnormal operation during repetitive movements

- Detection of abnormal operation during product transfer

- Detection of product omission

- Quality Anomaly Detection

-

- Product appearance inspection

- Detection of missing parts

- Detection of product mixing

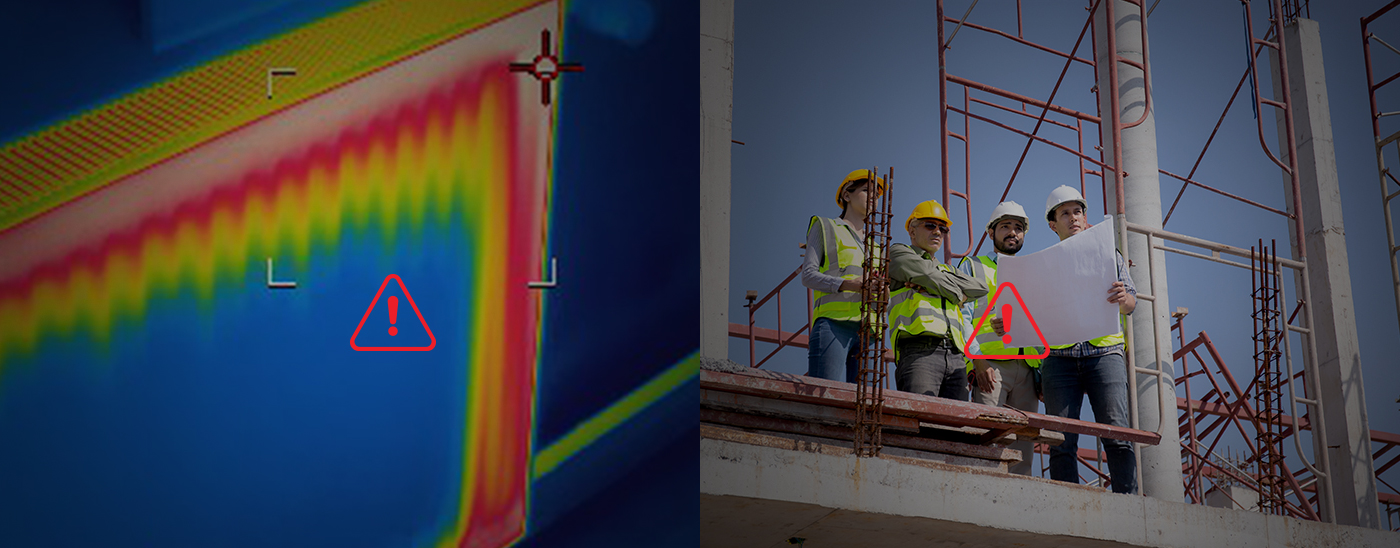

- Safety & Environment

-

- Detection of area-specific anomalies

- Motion detection

- Detection of equipment misoperation

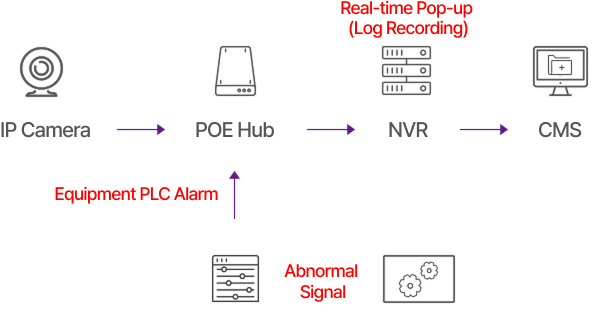

Monitoring System Steps

- step 01 Equipment Observation Stage

-

- Detection of area-specific anomalies

- Motion detection

- Detection of equipment misoperation

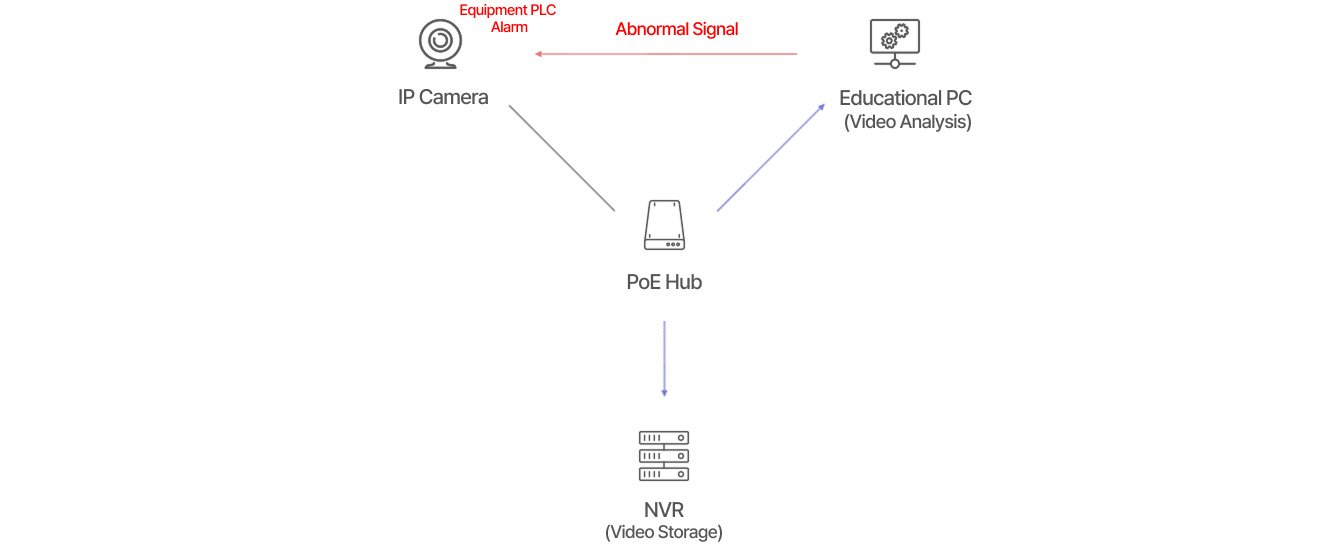

- step 02 Automatic Alarm Stage

-

- Integration with equipment PLC signals

- Pre/post-event recording upon PLC alarm

- Analysis support at the point of abnormal operation

- step 03 Active Alarm Stage

-

- Integration with AI-enabled PCs

- Application of abnormality detection

- Enhanced discrimination of equipment errors

Application Status

※ Note: Filtered due to security processes

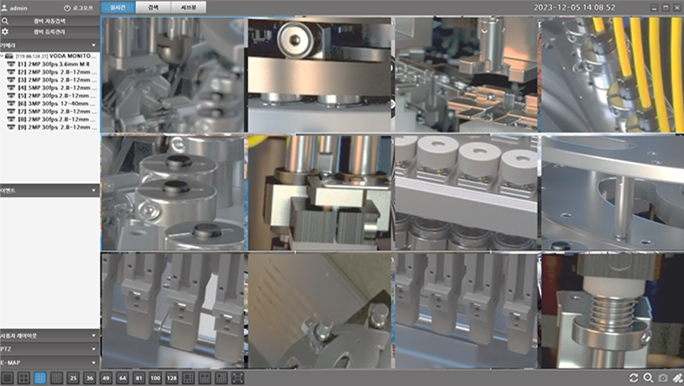

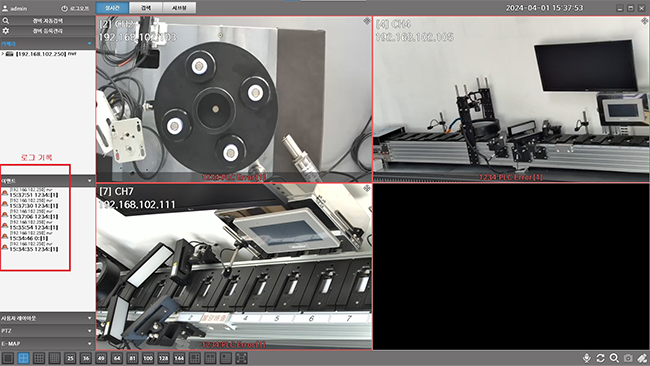

Monitoring System Screen Example

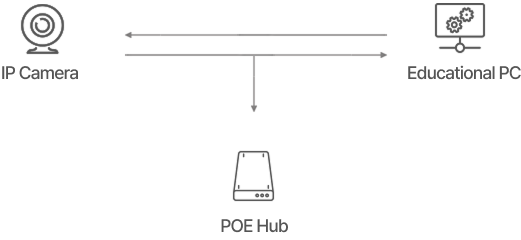

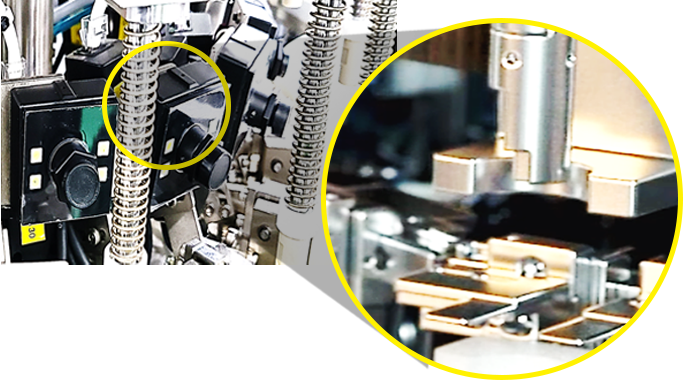

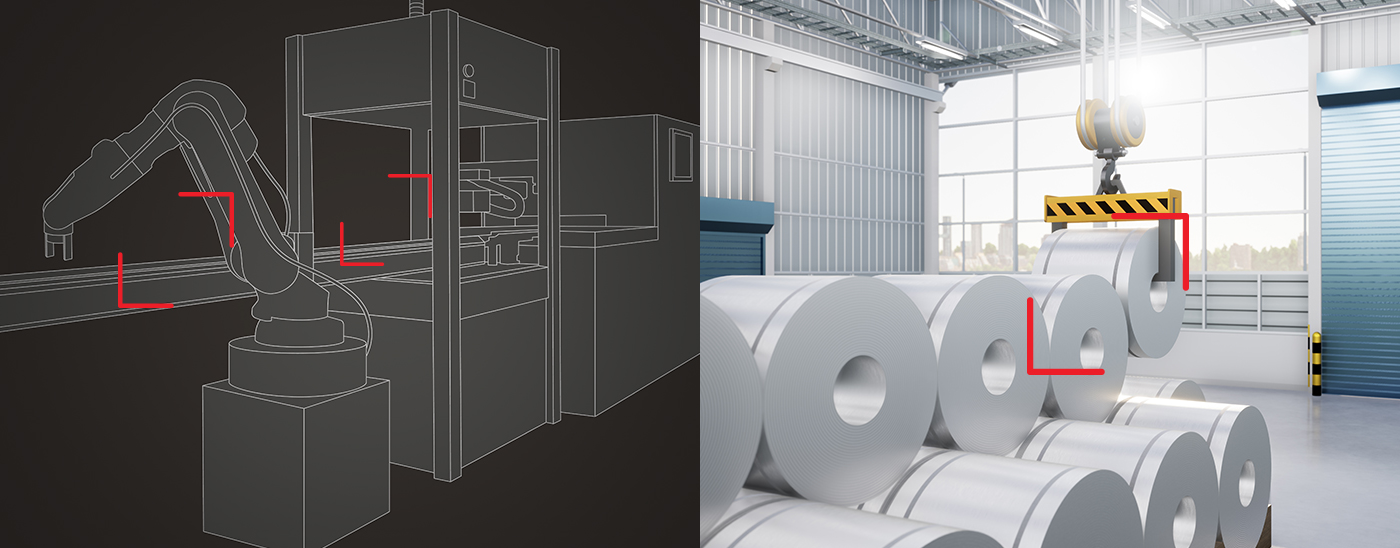

Installation Example 1

Expansion of detailed/narrow/hazardous processes

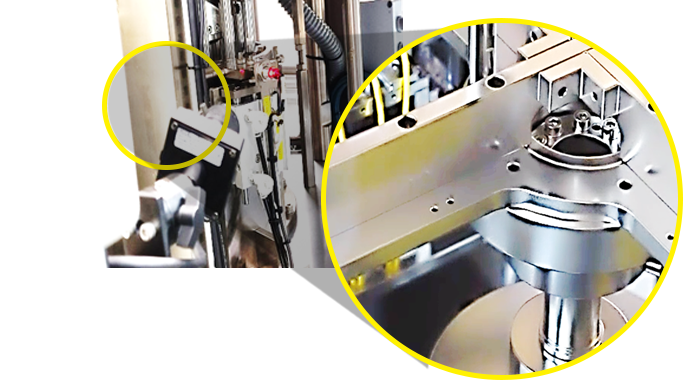

Installation Example 2

Expansion of detailed/narrow/hazardous processes

Installation Example 3

Understanding the overall process flow

Installation Example 4

Low-light/darkroom processes

Source: YouTube

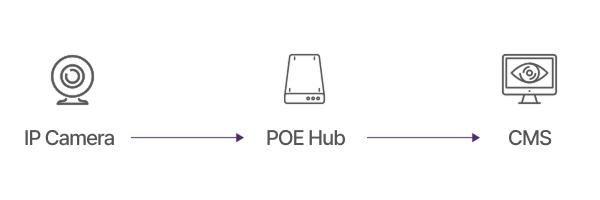

System Screen Example

PLC System Example

POP-UP after injecting 3 arbitrary PLC error signals in a split-screen view

Intelligent System Configuration

Intelligent System Application

Equipment Anomalies

Presence/Absence of Parts · Mixing · Misalignment · Foreign Material · Damage · Printing Error

Quality Anomalies

Worker Entry into Restricted Areas · Fire

Safety / Fire

Malfunction · Failure · Damage

Performance Aggregation

Automatic Product Performance Aggregation

Intelligent System Use Cases

Main Purpose

- Process Monitoring

- Supports the implementation of optimized workflows by monitoring the manufacturing process and production status in real time.

- Equipment Status/Location/Damage Monitoring

- Establishes an operational system that prevents accidents in advance and enables immediate response by monitoring production equipment in real time.

Other Applications

- Hazardous Material Management

- Supports rapid response by monitoring hazardous substances, toxic gases, and wastewater leakage in the workplace in real time and detecting anomalies early.

- Intrusion Detection & Fire Monitoring

- Establishes a system that enables immediate response by detecting intrusions, fires, and other anomalies in critical areas through real-time monitoring.

- Quality Inspection

- Enables quality control by analyzing product appearance, color, and other attributes through video analysis.

Intelligent System Inspection Cases

- Application of AI Deep Learning System

- Enhances inspection recognition rates in diverse environments where traditional inspection systems and sorting are vulnerable, thereby preventing claims and improving customer confidence in product quality.

*Reduces quality control costs and prevents claim occurrences by improving recognition rates at a lower cost compared to vision inspection

Uneven Surface

Curved Container

Curved Container

Application Status

Presence/Absence Inspection

Detects when a product is missing at the target position

Foreign Substance Inspection

Detects small defects (NG) present at the target position

High-speed Inspection

Detects defects (NG) on high-speed targets